Guide to CE marking for Pressure Equipment Directive PED 2014/68/EU

1. Pressure equipment

Vessels, piping, safety accessories and pressure accessories, including, where applicable, elements attached to pressurised parts, such as flanges, nozzles, couplings, supports, lifting lugs.

2. Vessel

A housing designed and built to contain fluids under pressure including its direct attachments up to the coupling point connecting it to other equipment. A vessel may be composed of more than one chamber.

3. Piping

Components intended for the transport of fluids, when connected together for integration into a pressure system. Piping includes in particular a pipe or system of pipes, tubing, fittings, expansion joints, hoses, or other pressure-bearing components as appropriate. Heat exchangers consisting of pipes for the purpose of cooling and heating air shall be considered as piping.

4. Safety accessories

Devices designed to protect pressure equipment against the allowable limits being exceeded. Such devices include: - devices for direct pressure limitation, such as safety valves, bursting disc safety devices, buckling rods, controlled safety pressure relief systems (CSPRS), and - limiting devices, which either activate the means for correction or provide for shutdown or shutdown and lockout, such as pressure switches or temperature switches or fluid level switches and 'safety related measurement control and regulation (SRMCR)' devices.

5. Pressure accessories

Devices with an operational function and having pressure-bearing housings.

6. Assemblies

Several pieces of pressure equipment assembled by a manufacturer to constitute an integrated and functional whole.

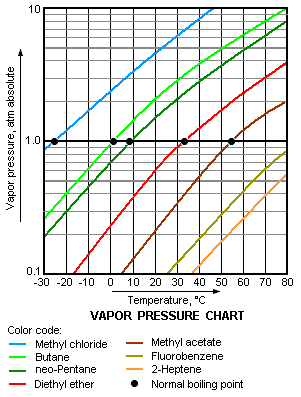

Gases, liquefied gases, gases dissolved under pressure, vapours, and also those liquids whose vapour pressure at the maximum allowable temperature is greater than 0.5 bar(g) above normal atmospheric pressure (1013 mbar) shall be classified as GAS.

Liquids having a vapour pressure at the maximum allowable temperature of not more than 0.5 bar(g) above normal atmospheric pressure (1013 mbar) shall be classified as LIQUID.

- A vessel filled with Methyl chloride and design temperature is 30 °C:

• Gas (vapour pressure > 0.5 bar(g), boiling point = -25 °C)

- Vessel filled with water:

• -109 °C: Liquid (vapour pressure < 0.5 bar(g))

• -110 °C: Liquid (vapour pressure = 0.5 bar(g))

• -111 °C: Gas (vapour pressure > 0.5 bar(g))

Note: This section contains a vapor pressure chart that shows the pressure (bar) vs. temperature (°C) for various substances, including Methyl chloride, Butane, neo-Pentane, Diethyl ether, Methyl acetate, Fluorobenzene, and 2-Heptene. A red line represents the vapor pressure of water.

The chart illustrates that when vapor pressure exceeds 0.5 bar over atmospheric pressure, the substance is classified as a gas; below that threshold, it is classified as a liquid.

Physical properties of fluids

GROUP 1 Consisting of substances and mixtures as defined in points (7) and (8) of Article 2 of Regulation (EC) No 1272/2008, that are classified as hazardous in accordance with the following physical or health hazard classes laid down in Parts 2 and 3 of Annex I to that Regulation:

- (i) unstable explosives or explosives of Divisions 1.1, 1.2, 1.3, 1.4 and 1.5;

- (ii) flammable gases, category 1 and 2;

- (iii) oxidising gases, category 1;

- (iv) flammable liquids, category 1 and 2;

- (v) flammable liquids, category 3 where the maximum allowable temperature is above the flashpoint;

- (vi) flammable solids, category 1 and 2;

- (vii) self-reactive substances and mixtures, type A to F;

- (viii) pyrophoric liquids, category 1;

- (ix) pyrophoric solids, category 1;

- (x) substances and mixtures which in contact with water emit flammable gases, category 1, 2 and 3;

- (xi) oxidising liquids, category 1, 2 and 3;

- (xii) oxidising solids, category 1, 2 and 3;

- (xiii) organic peroxides types A to F;

- (xiv) acute oral toxicity, category 1 and 2;

- (xv) acute dermal toxicity, category 1 and 2;

- (xvi) acute inhalation toxicity, category 1, 2 and 3;

- (xvii) specific target organ toxicity - single exposure, category 1,EN L 189/182 Official Journal of the European Union 27.6.2014

GROUP 1 comprises also substances and mixtures contained in pressure equipment with a maximum allowable temperature TS which exceeds the flashpoint of the fluid.

GROUP 2 Consisting of substances and mixtures not referred to in group 1.

Assemblies referred to in Article 4 (2) shall be subject to a global conformity assessment procedure comprising the following assessments:

Ident a)

the assessment of each item of pressure equipment making up the assembly and referred to in Article 4(1) which has not been previously subjected to a conformity assessment procedure and to a separate CE marking; the assessment procedure shall be determined by the category of each item of equipment.

Ident b)

the assessment of the integration of the various components of the assembly as referred to in points 2.3, 2.8 and 2.9 of Annex I, which shall be determined by the highest category applicable to the equipment concerned other than that applicable to any safety accessories;

Ident c)

the assessment of the protection of an assembly against exceeding the permissible operating limits as referred to in points 2.10 and 3.2.3 of Annex I, shall be conducted in the light of the highest category applicable to the items of equipment to be protected.

Choose a module from the category or a higher module

| CATEGORY | MODULE (Annex III PED) |

|---|---|

| SEP | Sound Engineering Practice |

| I | A |

| II | A2, D1, E1 |

| III | B+D, B+F, B+E, B+C |

| IV | B+D, B+F, G, H1 |

The internal volume of a chamber including the volume of nozzles to the first connection or weld and excluding the volume of permanent internal parts.

The maximum allowable pressure for the equipment, measured in bar (bar). This is the design pressure that the equipment is intended to withstand during operation. The higher the pressure, the stricter the safety requirements.

The nominal diameter of the piping or vessel, typically measured in millimeters. While diameter is not directly part of the PS×V classification, it influences the design and inspection requirements, especially for pipes and fittings. In some cases, the nominal diameter (DN) is used to determine thresholds for small vessels and piping, affecting the scope of PED applicability.

An unstable gas in this context is a gas or a vapour liable to itself spontaneously, producing a sudden pressure increase. Such transformation as an example can result from a relatively small variation of an operating parameter (e.g. pressure, temperature) in a confined volume.

This category covers portable fire extinguishers and breathing air bottles that fall under specific provisions of the PED 2014/68/EU directive.

Special Considerations:

- Portable fire extinguishers must comply with Annex III, point 1.4

- Breathing apparatus bottles require specific conformity assessment procedures

- Special marking requirements may apply

These items are subject to specific conformity assessment modules due to their portable nature and safety-critical applications.

Equipment designed for temperatures exceeding 350°C requires special consideration under PED 2014/68/EU due to material property changes at elevated temperatures.

Important Factors:

- Material selection must account for high-temperature properties

- Creep and fatigue considerations become critical

- Special testing and inspection requirements may apply

- Higher conformity assessment modules may be required

The 350°C threshold is significant as it often marks a point where standard material properties and design calculations need special consideration.